English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

- PVC Air Knife

- Stainless Steel Air Knife

- Aluminum Alloy Air Knife

- Air Knife Accessories

- PCB Horizontal Line Spares and Parts

- Pressure Gauges and Flow Meters

- Grinding Brushes

- Sponge Rollers

- Rubber Rollers for Water Retaining

- Hard Plastic Wheel Discs

- Soft and Rubberized Wheel Discs

- Flipping Machine Wheel Discs

- Middle Roller, Flange Roller and Plastic Bearing

- NBR Conveyor Discs and Bearing Seats

- Spacer and Locking Sleeve

- Screws

- Spur Gears

- Pin Gears

- Bevel Gears

- Helical Gears

- Double Gears

- Brackets or Holders

- Nozzles

- Nozzle Pipe&Nozzle Joint

- Filter Series

- Drive Holder and Bushing

- Transmission Parts

- Peripheral Functional Parts

- Seal Strip

- Grinding Machine Parts

- Liquid Level Switch

- Electroplating Parts

- Other Parts and Consumables

Rubber Rollers for Water Retaining

The rubber roller is a component used in the PCB production process to prevent liquid leakage. It is mainly used during the cleaning, coating, or etching processes of printed circuit boards to prevent water or chemical liquids from splashing or contaminating the surrounding environment.

Key Features:

1. Waterproof Function: Effectively prevents liquid leakage, keeping the work environment clean.

2. Durable Material: Made of high-quality rubber or synthetic materials, corrosion-resistant, wear-resistant, and suitable for long-term use.

3. Good Elasticity: Offers excellent elasticity and flexibility, adaptable to different equipment and operational requirements.

4. Easy Installation: Compact design, easy to install, compatible with various PCB equipment.

5. Pollution Reduction: Prevents chemical liquids or cleaning water from contaminating other equipment and the environment.

Application Scenarios

PCB Cleaning Process: Prevents cleaning liquids or water from splashing and protects equipment and the work environment.

Coating and Etching Processes: Prevents chemical liquids or solvents from leaking, ensuring process stability.

Other Equipment Protection: Used in other liquid handling processes to prevent contamination and loss.

The water blocking rubber roller is crucial in PCB production, effectively improving the cleanliness of the production environment, reducing liquid spillage and contamination, and enhancing production efficiency.

- View as

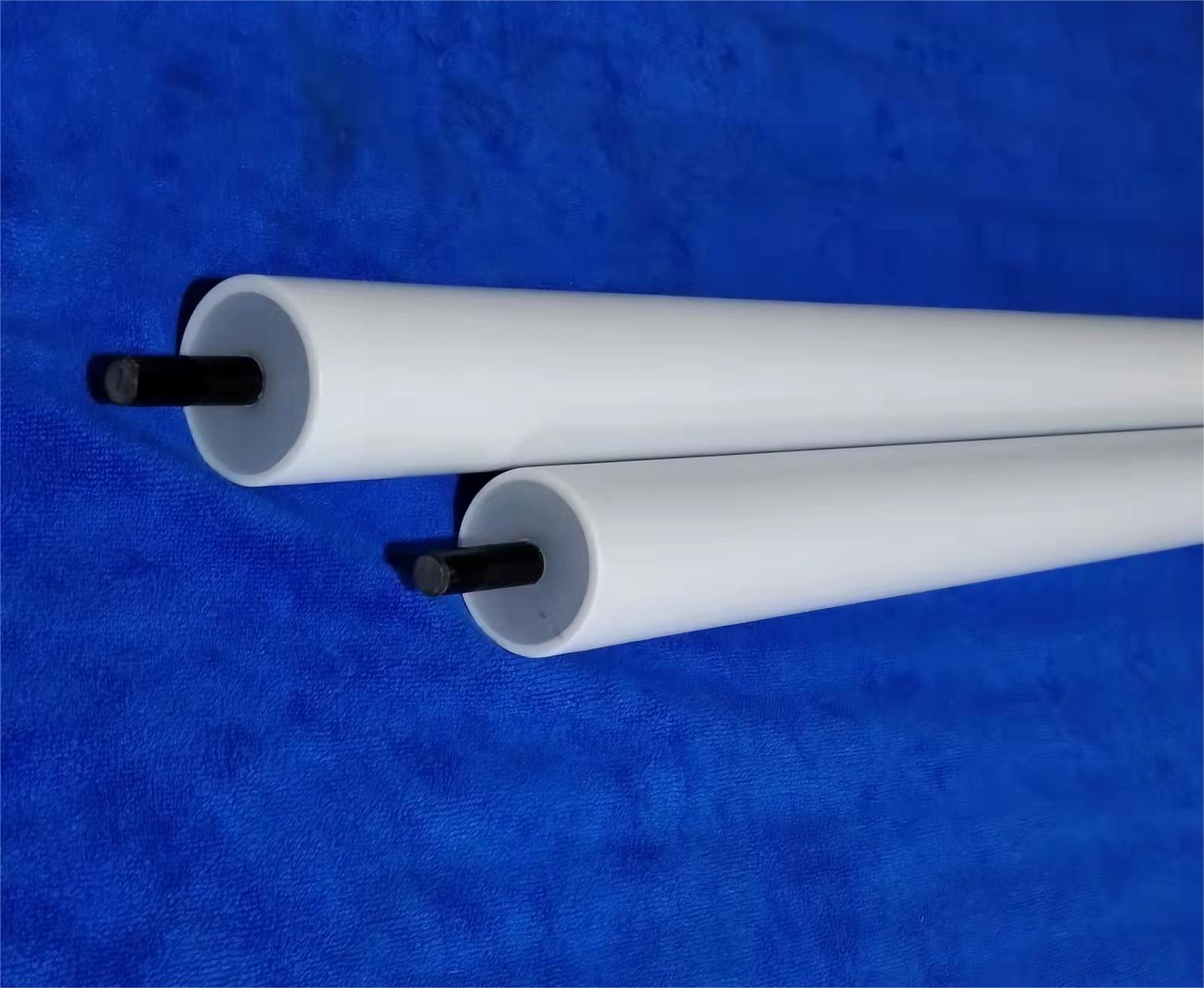

Teflon roller

SN:6-6 Name:Teflon roller Features:Resistant to strong acid and alkali, High temperature resistance, Excelent wear resistance Radial runout:0.15 mm Color: white Size:Can be customized

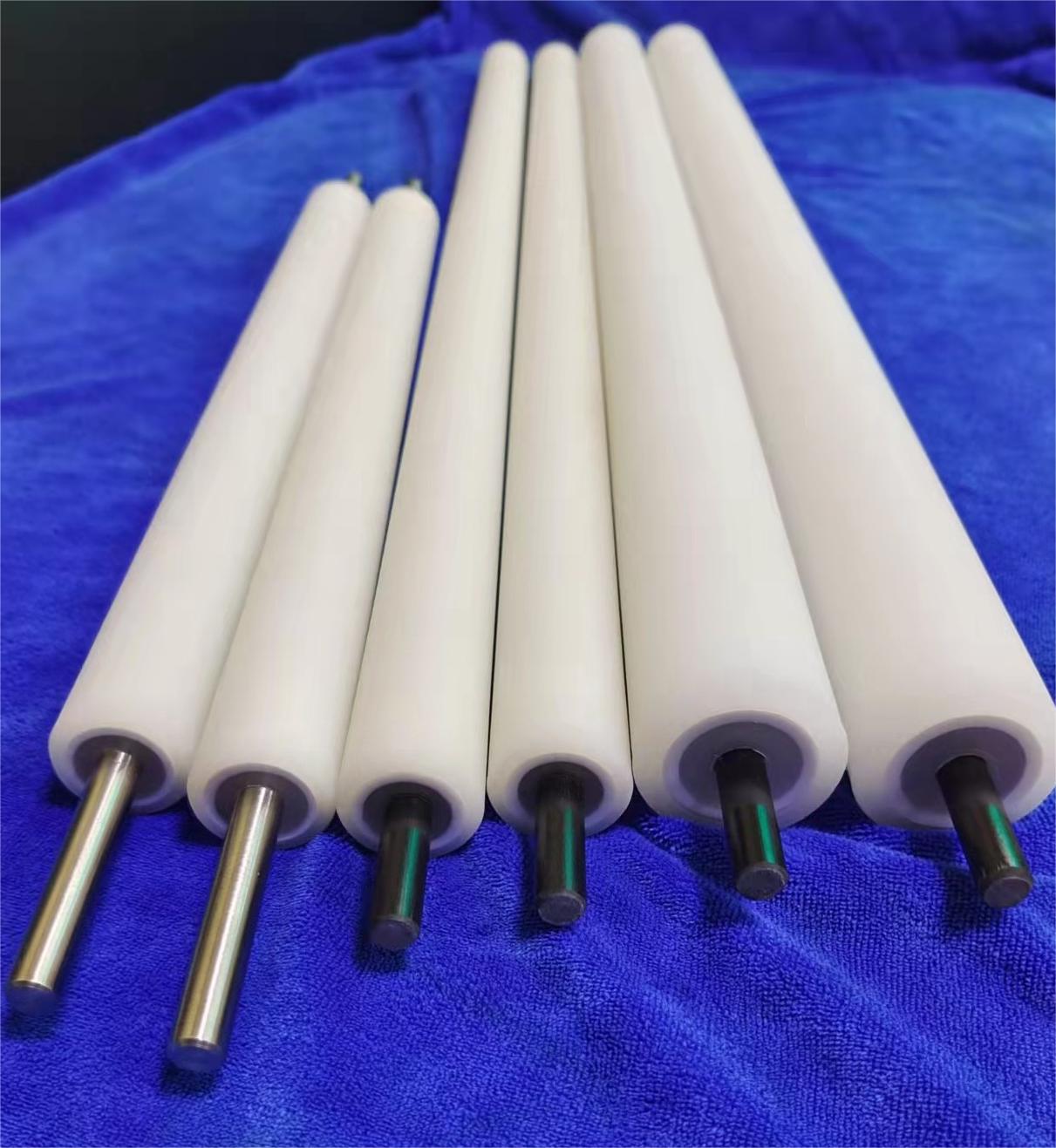

Read MoreSend InquiryTPV roller

Name:TPV Rubber roller Features: Resistant to strong acid and alkali Hardness:55-65 Color: White Heat resistance≤110℃, Radial runout:0.15 mm Size:Can be customized

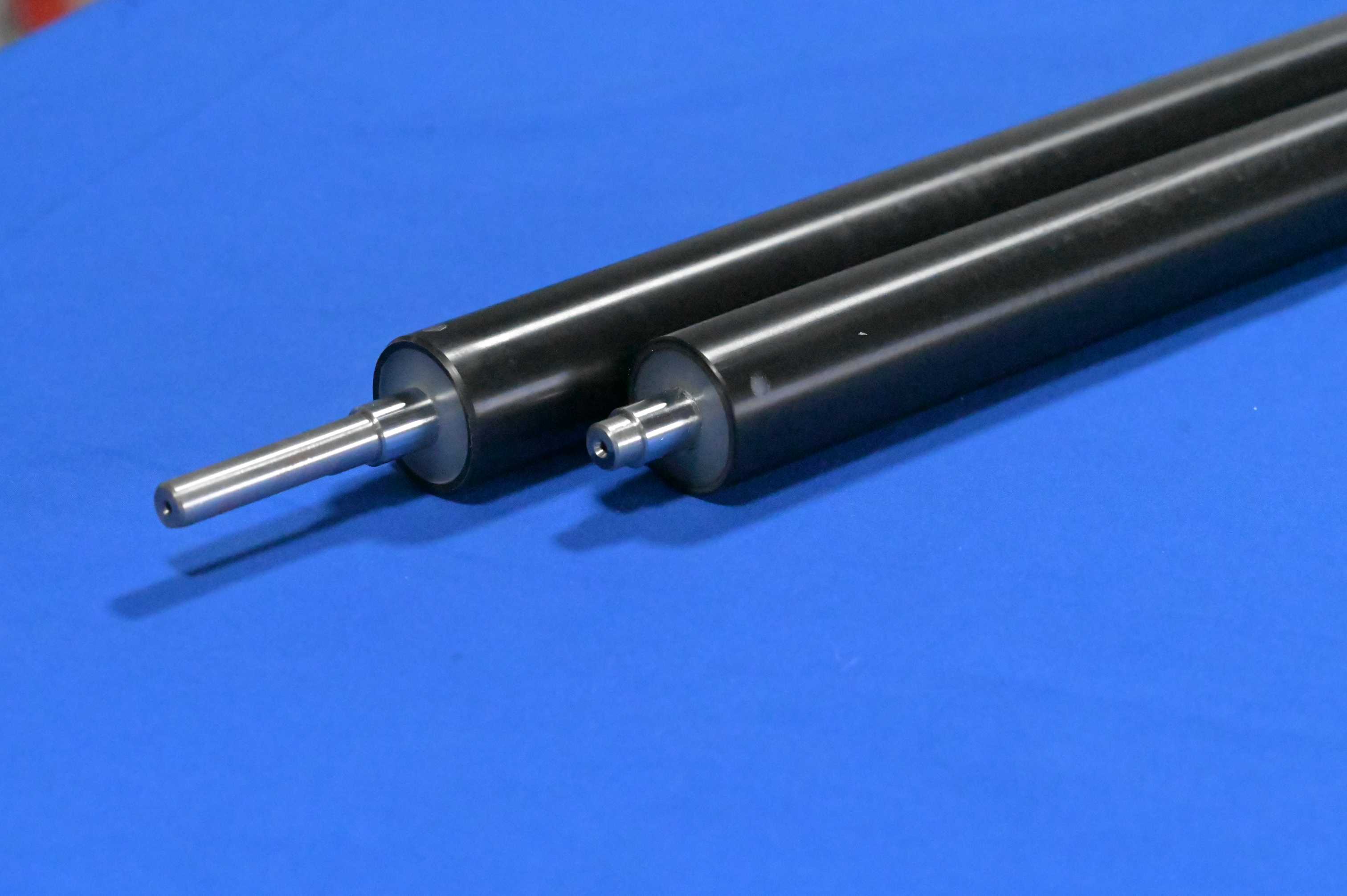

Read MoreSend InquiryPVC roller and EPDM roller

SN:6-4 Name:PVC/EPDM Rubber roller (for water retaining) Features:Resistant to weak acid and alkali, excellent water runoff performance,. Hardness:60-70 Color:Black Heat resistances 55℃,Radial runout:0.15 mm Size:Can be customized

Read MoreSend InquiryPP roller

Actually, our PP roller,its surface is smooth and wear-resistant, acid and alkali resistant, Hardness: 90-105, Heat resistance≦100℃, Fluctuation within 0.15mm, with this high quality rubber roller, it can improves production stability and efficiency on the premise of ensuring PCB quality.

Read MoreSend Inquiry